Page 1 of 2

Hmmm ... can this technique be ported to glass?

Posted: Sat Mar 09, 2013 9:38 am

by David Jenkins

Could some shinable alloy with a melting point compatible with glass be used to produce a glass piece that echoes this?

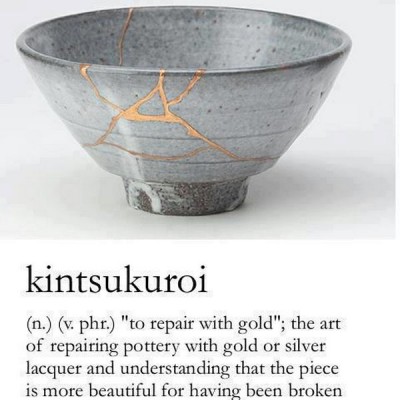

- Kintsukoroi

Re: Hmmm ... can this technique be ported to glass?

Posted: Sat Mar 09, 2013 9:52 am

by JestersBaubles

Silver clay?

PMC3 can be fired as low as about 1100 for 30 minutes (other formulas ~1400-1600 deg f). You would have to consider shrinkage (10% off the top of my head...) and it would be darned expensive. An option would be to keep the bowl intact and apply a silver clay paste to the surface to mimic the cracks.

Dana W.

Re: Hmmm ... can this technique be ported to glass?

Posted: Sat Mar 09, 2013 9:58 am

by JestersBaubles

Another random, possibly silly, thought... a non-fusing option could potentially be silver solder. Wrap the pieces with copper foil, put the broken pieces back into the mold, solder the inside, and then remove the bowl to complete the outside.

Obviously not as smooth as you would probably like.

Dana W.

Re: Hmmm ... can this technique be ported to glass?

Posted: Sat Mar 09, 2013 9:58 am

by Bert Weiss

Hxtal repairs of broken glass, stick the glass together, but do not mask the break, just like pottery. You could certainly paint over the seams with gold lacquer. I don't think the pottery was fixed using heat, just glue and lacquer paint.

When glass with internal stresses breaks, the stresses re-align. So the pieces of glass actually change shape after they break. So, gluing them back together is never perfect. I know less about stress in pottery, but common sense tells me it could be quite similar. We know that you can not re-fuse broken glass to it's original state because glass shrinks as it softens, then flows as it gets hotter and softer. This makes a refire catch as catch can.

Re: Hmmm ... can this technique be ported to glass?

Posted: Sat Mar 09, 2013 11:02 am

by Kevin Midgley

electroforming/electroplating using copper sheet/foil and a plating solution.

Re: Hmmm ... can this technique be ported to glass?

Posted: Sat Mar 09, 2013 11:12 am

by Morganica

I'd stay as true to the original intent as possible: Use the same technique, but substitute glass for pottery.

I have a method of repairing cast work where I rebuild the broken areas with organic wax that will burn out, then enclose the whole piece in refractory plaster and refire. You could try a variation of that maybe with a CMC+frit filler in a different color, maybe layered with gold or silver foil. Might be difficult to keep the foil from vaporizing, though.

Re: Hmmm ... can this technique be ported to glass?

Posted: Sun Mar 10, 2013 7:10 am

by David Jenkins

Looks to me that this is one of those things that would take much, much experimentation/testing to perfect, but the payoff would be awe-inspiring, I think. Some good ideas here - thanks.

Re: Hmmm ... can this technique be ported to glass?

Posted: Sun Mar 10, 2013 10:25 am

by Valerie Adams

I think the biggest challenge would be selling the "understanding that the piece is more beautiful for having been broken."

Re: Hmmm ... can this technique be ported to glass?

Posted: Sun Mar 10, 2013 10:34 am

by Brock

Valerie Adams wrote:I think the biggest challenge would be selling the "understanding that the piece is more beautiful for having been broken."

Yeah! And why do it?

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 7:56 am

by David Jenkins

"Why do it?"

Well, we're definitely in the subjective realm here, but I think the piece shown in the image above demonstrates a different kind of beauty than would a similarly shaped pottery piece with the same finish, etc., but unveined. The gold veins have introduced a particular element of randomness that I haven't seen in glass before (unfortunate accidents notwithstanding) and I find that very pleasing. YMMV.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 9:36 am

by Brock

My mileage DOES vary. This is just another example of slapping another technique onto glass. And, it shows no respect to an ancient tradition to cheaply copy it.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 9:49 am

by Bert Weiss

David Jenkins wrote:"Why do it?"

Well, we're definitely in the subjective realm here, but I think the piece shown in the image above demonstrates a different kind of beauty than would a similarly shaped pottery piece with the same finish, etc., but unveined. The gold veins have introduced a particular element of randomness that I haven't seen in glass before (unfortunate accidents notwithstanding) and I find that very pleasing. YMMV.

David, one of my favorite stained glass windows was made by Albinus Elskus. He painted a nude on a single piece of glass. I forget the exact story. It dropped and shattered, either by accident or on purpose. There were large pieces and shattered sections. He leaded it back together, and replaced the shattered sections with mirror. There is a photo in his book, but you can't tell from the photo that there is mirror in it. I saw the piece in person, at the home of Bill Cummings, and it was stunning. He particularly liked the way this transformed the piece from a nude painting to a conceptual piece, saying much more. I looked for an image on google, but didn't find it.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 9:57 am

by Brock

There is a long history of re-leading broken pieces in stained glass.

That has nothing to do with the subject of this thread.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 10:11 am

by bob proulx

You could mirror it with a bronze mirror kit from angel gilding.

http://angelgilding.com/mirror-kits.html

You mask the piece your working on, cut the design and pour the mirroring solution.

Bob

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 10:54 am

by Bert Weiss

Brock wrote:There is a long history of re-leading broken pieces in stained glass.

That has nothing to do with the subject of this thread.

There is a long history of you making irrelevant objections to relevant postings.

The thread is about piecing back together a broken object, and accentuating the organic break lines. And, specifically, how this enhances the piece.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 10:58 am

by Brock

. . . piecing back together a broken object . . . not a window. Figure it out.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 12:00 pm

by Valerie Adams

Definitely a matter of personal taste, but the idea of one of us accidentally breaking a piece, and then figuring out a way to bandage it back together and then call it 'enhanced' reminds me too much of the pieces I see with bubbles blown through them being named things like "Eye of the Storm." Intentional design is something I work hard to achieve so it annoys me to see failures passed off as design. Silk purse from sow's ear is one thing; if something is truly made better by manipulation, I'm all in. But most often what I see amounts to polishing turds.

As hard as it is to discard pieces that don't survive the process (at whatever the stage they were in), there's a learning experience that's more valuable to me than selling substandard work.

Now obviously, I know there are exceptions, like pieces in museums. But until my work is of that quality, broken pieces in my studio are given a decent farewell and good riddance.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 12:05 pm

by Brock

Totally agree Valerie. It's like breaking a sculptural float glass piece, then saying you like the break. It's an evasion, it's dishonest, and ultimately cheapens your work.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 12:52 pm

by Bert Weiss

Brock wrote:Totally agree Valerie. It's like breaking a sculptural float glass piece, then saying you like the break. It's an evasion, it's dishonest, and ultimately cheapens your work.

BULLSHIT!

I once made a 7' tall, 10mm thick, sculptural fountain for a flower show installation. The show was in Maine, in March, in a giant tent. Somebody left a tent flap open, the very cold night before it was to be heated for the flowers. It was cold in there. The gas company came in and really cranked on the heaters. Much later in the day, my collaborator turned the water on, to flow down the glass. The room temperature by that point was 30º warmer 10' off the floor than at waist height (glass mounted 3' off the floor). The water temperature was somewhere around 34º. Needless to say, in 10 minutes, my glass cracked, and a section of the top came easily off, leaving an organic diagonal line. I had left the site for the day. My collaborator called in a panic. In the morning, I brought in my belt sander and softened the sharp edges. In the end, the broken glass gave the installation an ancient artifact feel that enhanced the design which featured Greek columns and hanging ferns. We had to turn down the water pressure to deal with the missing glass on top. But all in all I thought it looked better and was quite pleased with our outcome. I later sold the piece to a client for his outdoor garden. There was no evasion. The work was honest. And certainly not cheapened. I am not the first person to be dealt a lemon and ended up with lemonade.

Re: Hmmm ... can this technique be ported to glass?

Posted: Mon Mar 11, 2013 1:12 pm

by Brock

HEY! Watch the language there, Fracture Boy . . .